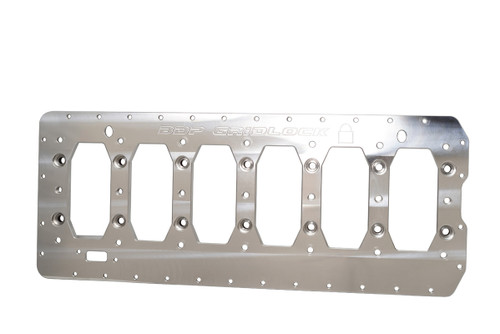

Bean Machine Billet Aluminum Gridlock Girdle – GIRDLE ONLY

Precision. Strength. Simplicity.

The Bean Machine Gridlock Girdle for Cummins Common Rail engines was built with a single goal: to offer maximum structural reinforcement without the typical headaches found in other girdles. We’ve eliminated the flaws we encountered firsthand — weak spacers, oil pan clearance issues, and unreliable hardware — and engineered a streamlined, lightweight solution that delivers uncompromising strength.

Engineered for Strength Under Pressure

Our girdle design locks the main caps in place using steel dowel inserts and ties together the entire lower end of the engine block — right out to the outermost bolt holes. Preload set screw ports above each main cap allow for additional clamping force, helping prevent distortion or walk under the stress of high horsepower applications.

Why Aluminum Over Steel?

While other girdles are made from tool steel, we took a smarter approach. Yes, tool steel is strong — but it’s also excessively heavy, slow to machine, and overkill for this application. Our aircraft-grade billet aluminum design is over twice as thick as most steel girdles on the market, giving it superior tensile strength and significantly less weight.

And thanks to steel-reinforced stud inserts, we eliminate aluminum compression and precisely align the girdle with the block via integrated dowel features. The girdle is also O-ringed for a reliable, leak-free seal.

Clean Fitment. No Compromises.

This is the same Gridlock Girdle featured in our complete kits — just the girdle itself for those who already have the hardware. Whether you’re doing a fresh build or upgrading your current setup, this is the foundation you want underneath your Cummins.

Proudly Made in Tennessee, USA

Looking for the complete kit? Check out our Gridlock Girdle Kit options with or without ARP studs.

Have fitment or customization questions? Reach us anytime at sales@bdpshop.com.

Gridlock Girdle Installation Instructions